The new T9 wireless magnetic levitation ultra-high-speed placement machine

LED placement machine

MOQ :1 set

Lead Time :30 Days

Seller Support : Trade Authenticity Guaranteed & Accepting

Payment : L/C,T/T,Western Union, Money Gram, Credit Card, Paypal

Product details

Supply Ability

- Supply Ability:1000 piecesWarranty(Year):1 Year

Product Specifications

- Brand name:ETON

Product Description

The Professional Supplier of LED Pick and Place Machine

Product Description

1.Features

Dual system,dual mode multi-functional high-speed mounter

Non-stop refueling capabilities.

Electronic feeder feeding system.

IPC9850 Capacity: 85000 CPH

Apply to the SMT machine, PCB,LED hard light board and LED soft lamp strip etc.

Apply to mounting LED,capacitors,resistors,IC,shaped components etc.(intelligent,use widely)

18 nozzles altogether,40 feeders,partA or partB can be mounted separatly. Easy to operate.

Patent Number: ZL 2011 2 0237740.9/ZL 2011 2 0334606.0

ZL 2012 2 0178869.1/ZL 2012 2 0415505.0

ZL 2012 2 0415044.7/ZL 2012 2 0415356.8

ZL 2012 2 0415061.0

2.Technical Parameter

| Length | 2950mm |

| Width | 2150mm |

| Height | 1500mm |

| Total Weight | 2000KG |

| PCB Length Width | Max.:350mm*1200mm Min.:50mm*50mm(W*L) |

| PCB Thickness | 0.5~3mm |

| PCB Clamping | Adjustable Pneumatic |

| Mounting Mode | Group picking and group placing or placing separately |

| Software | Windows XP |

| Display | LED Monitor |

| Input Device | Keyboard,Mouse |

| No. of Camera | 4 sets of imported camera/Vision alignment,Mark correction |

| Mounting Precision | ±0.02mm Chip |

| Mounting Height | 13mm±2 |

| Mounting Speed | 85000CPH |

| Components | LED,capacitors,resistors,shaped components etc. |

| Components Space | 0.2mm |

| No. of Feeders | 40PCS |

| Power | 380AC 50HZ |

| Power Comsumption | 6KW |

| Air Force | 0.5mpa |

| Operating Environment | 23℃±2℃ |

| Conveyor Transmission | Max Length:1.2m, Belt drive |

| Transmission Speed | >500mm/sec. |

| Transmission Direction | single (left→right or right→left) |

| Transmission Mode | Online Drive |

| Position Mode | Optical |

| Air Pressure | >5.0kg/cm2 |

| Air Consumption | <200L/min. |

| Electrical Control | Research and Develop Independently by ETON |

| Motion Control Card 2 sets | Research and Develop Independently by ETON |

| X,Y Axies Driving | Servo motor control for X,Y,Z axies |

| Feeder Type | Electronical Feeder |

3.Our Advantage

Date Analysis Compared with other Manufacturers

Manufacturers Parameter | Other company's F130 mounter | Other company's 5M168 mounter | Our Eton's HT-X7 mounter | Our Eton's HT-E3T mounter | Data Comparision |

| Speed | 15000CHP | 18000CHP | 100000~120000CPH | 70000~80000CPH | 6 to 8 times higher than others |

| Nozzle | 4 PCS | 6 PCS | 30 PCS | 45 PCS | 5 to 8 times higher than others |

| Precision | 0.03mm | 0.03mm | 0.02mm | 0.02mm | More Precise |

| Patent | __ __ | __ __ | Technology Patents | Technology Patents | Global First |

| Cost Performance | 20% | 30% | 100% | 100% | 3 to 5 times higher than others |

4.Production Image

Package and shipping

Package: Standard export package(It also can be adjusted according to customer's requirement)

Shipping: Shenzhen port within 30 days after payment

After-sale Service

Excellent After-sale Service.

Maintenance Period: 1 year(whole machine).

Visit customer regularly and gather information.

Provide latest information about technology and equipment.

Company Profile

The Global Largest Production Supplier of LED Placement Machine

Professional Efficient Technology Development Innovation

Company Five Level Management Policy: sincere business, focus on R&D, manufacture by heart, considerate service, customer trust.

Eton Purpose: to create value for customers, creating benefits for society.

Eton Mission: Professional,Excellent technology,Share the results.

Patents Certifications

Cooperative Partners

FAQ

1.What's LED pick and place machine?

As we know,LED is used popularly all over the world,so the demands and requirements of LED production line are increasing rapidly.And the LED pick and place machine is the most important part in producing LED light. Patching the LED is the key process.

2.What are the normal requirements about LED pick and place machine?

Because the patch is the key process in producing LED,there are many normal requirements:Stable,High-speed,High-precision, Intelligent,Durable etc..

3.What are the main LED products do our machines for?

There are different machines in our company,and different machines apply to different LED lights. The main products we can apply:bulb,tube,strip,lamp,panel,downlight,streetlight,ceiling light,wall washer light and so on.

4.Do our machines only for LED lights?

No,our machines apply to not only LED light but also other products.

5.What components do our machines apply to?

Our machines can patch LED 3014/3020/3528/2835/5050/5630/5730 etc.,capacitors,resistors,IC,shaped components and so on.

6.Why do we adopt the smart electronic feeders?

Our machines adopt the smart electronic feeders which are more stable,universal and intelligent. The feeding speed of electronic feeder is faster than the traditional pneumatic feeder.It can avoid the cast and drop of materials effectively.

7.What the highest production capacity and precision of our LED pick and place machine?

Our machine's production capacity can reach 120000 components per hour. It is the highest capacity in the field of LED pick and place machine.Our precision can reach 0.02mm,we adopt visual positioning,flight identification mark correction and smart industrial control system.

8.What about our technology patents and certificates?

We have got many technology patents which is the gobal first invention. The global first way:Group picking and group placing. We have rich experience in researching and developing and got SIRA and CE certificate.We are approved as the national high-tech enterprise by the country.

9.What's about the guarantee of the machines?

The maintence:1 year whole machine,any parts need to be repaired or replaced will be free. We will take the responsibility of the machines from A to Z.

10.What about our Eton's spirit?

We are concentrating on building international well-known brand,so the feedback of clients is very important to us.What we can provide are professional machines,supports and service.

You May Like

- Exhibitor

- Free Member

- Trade Assurance

Business Type : Manufacturer

Company Location: GUANG DONG

Year Established: 18YRS

You May Like

-

The new T9 wireless magnetic levitation ultra-high-speed placement machine

-

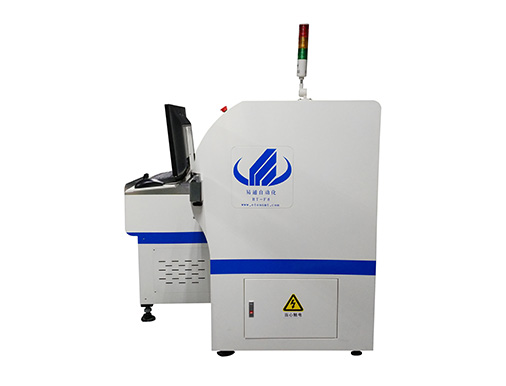

New product HT-F9 magnetic levitation high-speed placement machine

-

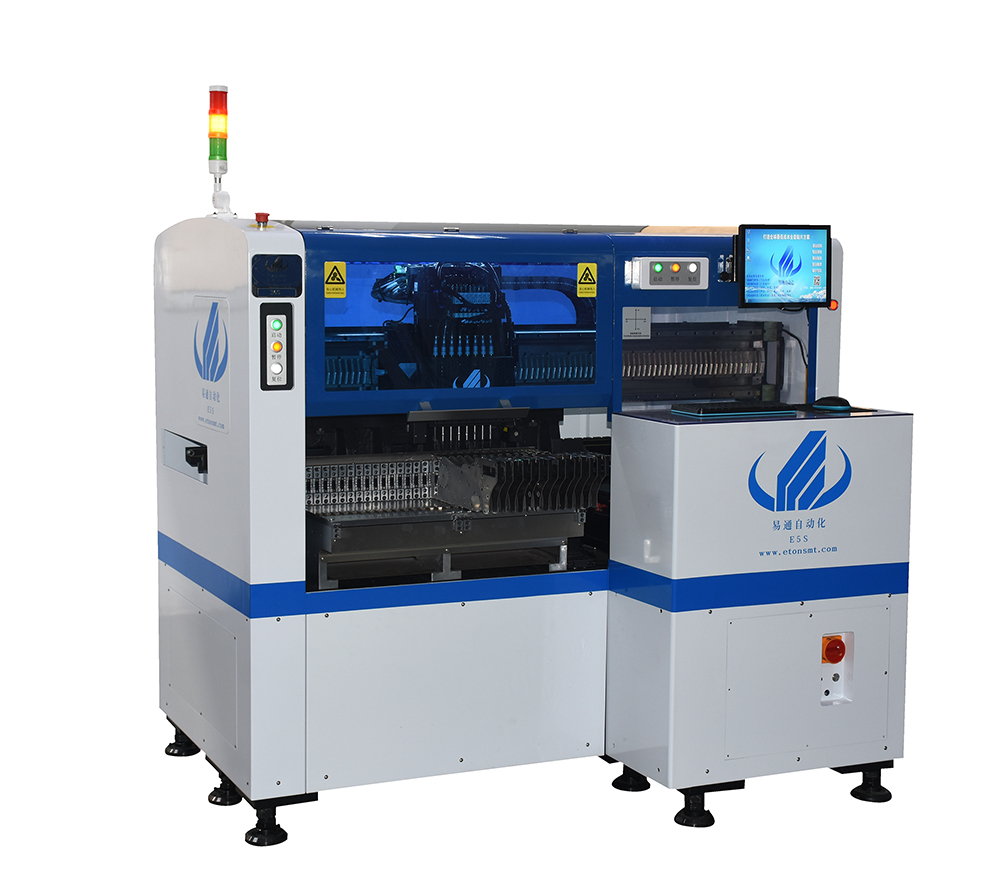

HT-E5S single module magnetic levitation multifunctional placement machine

-

HT-D12 automatic dispenser

-

HT-F8 display dedicated LED high-speed placement machine

-

LED SMT

-

HT-E5S single module magnetic levitation multifunctional placement machine

-

ETON LED placement machine

-

The LED placement machine

-

LED placement machine